We use Glodian Enfren

100% PVC-free film

We care about the safe future of our planet

It’s about conscious choices!

In Refloactive we pick our suppliers and source materials very carefully, to make sure we always offer our customers the best option there is. When analyzing reflective foil qualities, we take several things into consideration: one of them is the environmental impact of the material. That is why we are so keen on using Reflomax’s recent innovation: Glodian™ Enfren - a chloride free reflective film with excellent high frequency welding properties.

It’s a 100% Non-PVC , contains no chloride, no phthalate, and no plasticizers - without compromising its excellent properties.

All the certification you will ever need

Reflective silver foil Enfren, in addition to the absence of PVC content, is certified by SGS for the safe chemical composition of the product and for the reflective parameters - it meets the requirements of the most demanding reflective standard EN 17353, which means that items made from it are suitable for use as a means of personal protection for a pedestrian or cyclist in traffic. A user equipped with this reflector is visible from a distance of 300 meters.

Offer them the best!

This way, by getting reflectors manufactured by Refloactive, you are obtaining a product of the highest, EN certified quality which is safer for the environment. Your clients can be sure that not only packaging, but also the source materials in the reflectors meet the standards of eco-friendly. This is an obvious advantage in a world that is becoming more and more ecologically conscious and wants to make informed choices regarding their customer decisions.

Find out about our quality

Partner with the best

To make sure you meet the highest eco standards, you need to collaborate with the market leaders that introduce positive change. Korean Reflomax is a true innovator, constantly looking to raise the bar in the field of reflective tapes.

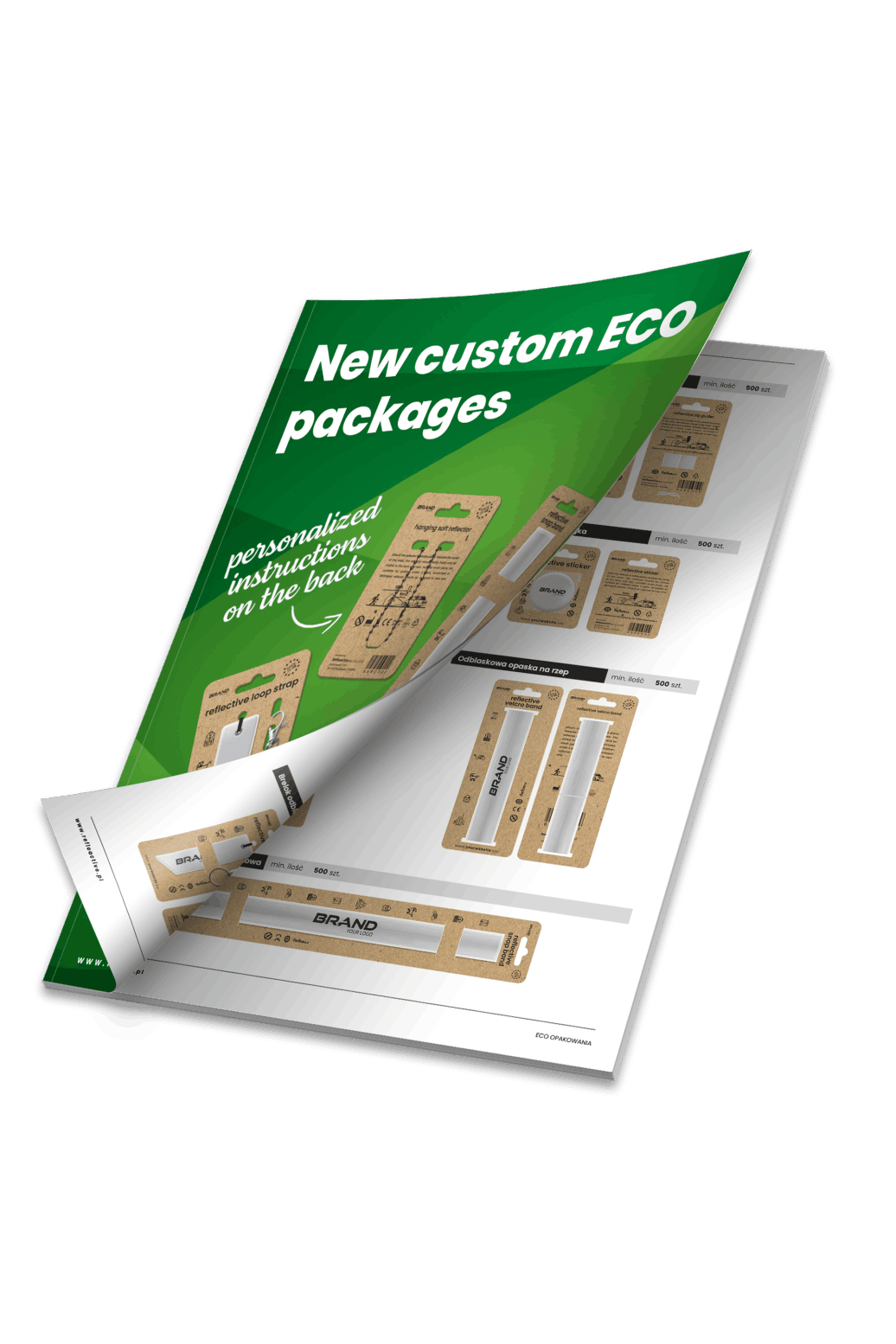

Now plastic can be eco!

A real revolution in the plastic packaging market!

What can you gain from our eco film packaging?

By betting on eco packaging from Polish production, you can strengthen your company's green image. Your logo will be on packaging that does not litter the environment - this is not only a great business benefit, but also a step towards a better tomorrow.

Consumers are also becoming more aware and are more willing to use products with biodegradable packaging. This is no longer a niche market - it is a trend that is becoming the norm. Adapting to these expectations is not only a matter of ethics, but also a matter of competitiveness. Companies that fail to adapt to this change could lose customers and find themselves on the margins of the market.

Gain competitive advantage. The search for new, more sustainable ways of doing business often leads to the discovery of new technologies, products and services. This can bring companies not only financial benefits, but also a competitive advantage.

What is PLA film?

PLA film is an environmentally friendly, biodegradable and compostable film. The ingredients for its production are derived from biopolymers based on corn kernels.

Eco film was developed as an alternative to petrochemical-based sources. It is FDA-certified for food contact and certified biodegradable and compostable according to the EN 13432 standard.

Why is being eco important to us?

First and foremost, we believe that being eco is about taking care of our planet and future generations. All our actions have an impact on the environment, and the natural resources we use are limited. Businesses have a huge impact on society and the environment. How we conduct our businesses affects the world around us. With this in mind, we must take responsibility and act in a way that is sustainable and respectful of the planet. This is not a matter of choice - it is our responsibility. If not us, then who? If not now, then when?

Advantages of PLA film

🌽 100% compostable

🌽 Manufacturing processes are environmentally friendly

🌽 Has high purity, transparency and high gloss

🌽 Exhibits excellent processability (natural surface tension of 38 dynes)

🌽 Good sliding properties

🌽 Excellent resistance to fats and oils

🌽 Low water vapor barrier, which prevents the fogging effect

Application

Biofoil made from corn polymers is excellent for:

🌽 for laminating

🌽 for packaging

🌽 for windows in envelopes, boxes